flange center plate butterfly valve

technical parameter

pressure range:class150~class600 (pn6~pn16)

nominal diameter:nps2"~120"(dn50~dn3000)

body material:carbon steel, stainless steel, duplex stainless steel, alloy steel, ductile iron

end connection:flange

temperature range: -40℃~120℃

drive type:worm gear device

design standard:api 609,awwa c504,gb/t12238,gb/t13927

product structure features

1.driving device:can be equipped with a handle, worm gear, electric or pneumatic control device.

2.bushing:reduce the rotational torque, support the stem, and make it separate from the body effectively, reduce the wear of the valve stem.

3.surface of disc axle hole:after polishing treatment, with the seat precision.

4.high precision disc external profile:to achieve zero leakage requirements of air tightness test. the opening and closing torque is small, prolong the service life of the seat.

5.stem seal:stem seal is not easy to deform, thereby avoiding the usual stem leakage.

6.strong precision key:the utility model has the advantages of high precision and high strength, and is suitable for the installation of the handle and other control devices.

7.precision taper pin:the utility model is characterized in that the valve rod and the valve plate are firmly connected with the valve plate, and the utility model has the characteristics of anti vibration and easy replacement.

8.integral stem design:high precision, high reliability, easy to control the opening and closing of the valve plate.

9.body lined with rubber seat:good overall stability, stable, tensile, anti leakage.

10.o-ring:auxiliary shaft end leakage.

the main technical parameters

| nominal diameter | dn(mm) | 50~2000 | ||

| nominal pressure | pn(mpa) | 0.6 | 1.0 | 1.6 |

| test pressure | strength test | 0.9 | 1.5 | 2.4 |

| seal test | 0.66 | 1.1 | 1.76 | |

| air tightness test | 0.6 | 0.6 | 0.6 | |

| applicable media | air, water, sewage, steam, gas, oil, etc. | |||

| drive form | manual, worm and worm gear drive, pneumatic drive, electric drive | |||

material of main parts

| part name | material |

| body | all kinds of rubber, ptfe |

| disc | grey cast iron, nodular cast steel, cast steel, stainless steel and special materials |

| sealing ring | ductile cast steel, cast steel, alloy steel, stainless steel |

| stem | 2cr13, stainless steel |

| packing | o-ring, flexible graphite |

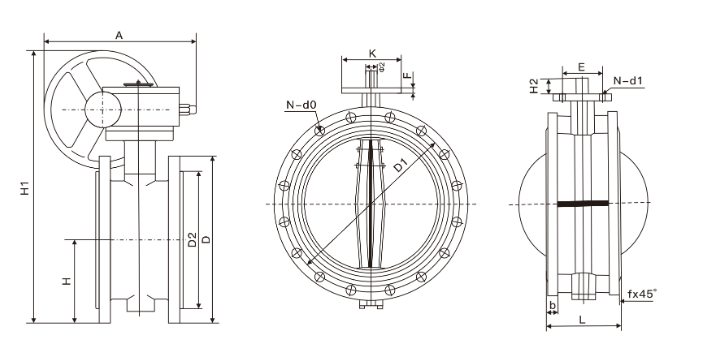

main dimensions and weight (pn1.0/1.6mpa)

| dn | l | d | d1 | d2 | b | f | n-d0 | a | k | e | f | h | h1 | h2 | φ2 | n-d1 |

| 50 | 108 | 165 | 125 | 102 | 18 | 3 | 4-φ18 | 180 | 65 | 50 | 13 | 83 | 338 | 28 | 12.6 | 4-φ7 |

| 65 | 112 | 185 | 145 | 122 | 18 | 3 | 8-φ18 | 180 | 65 | 50 | 13 | 93 | 358 | 28 | 12.6 | 4-φ7 |

| 80 | 114 | 200 | 160 | 138 | 20 | 3 | 8-φ18 | 245 | 65 | 50 | 13 | 100 | 413 | 28 | 12.6 | 4-φ7 |

| 100 | 127 | 220 | 180 | 158 | 20 | 3 | 8-φ18 | 240 | 90 | 70 | 13 | 114 | 428 | 28 | 15.77 | 4-φ10 |

| 125 | 140 | 250 | 210 | 188 | 22 | 3 | 8-φ18 | 240 | 90 | 70 | 13 | 125 | 444 | 28 | 18.92 | 4-φ10 |

| 150 | 140 | 285 | 240 | 212 | 22 | 3 | 8-φ22 | 350 | 90 | 70 | 13 | 143 | 553 | 28 | 18.92 | 4-φ10 |

| 200 | 152 | 340 | 295 | 268 | 24 | 3 | 12-φ22 | 350 | 125 | 102 | 13 | 170 | 678 | 38 | 22.1 | 4-φ12 |

| 250 | 165 | 405 | 355 | 320 | 26 | 3 | 12-φ26 | 550 | 125 | 102 | 13 | 198 | 742 | 38 | 28.45 | 4-φ12 |

| 300 | 178 | 460 | 410 | 378 | 28 | 4 | 12-φ26 | 600 | 125 | 102 | 20 | 223 | 803 | 38 | 31.6 | 4-φ12 |

| 350 | 190 | 520 | 470 | 438 | 30 | 4 | 16-φ26 | 600 | 150 | 125 | 20 | 270 | 866 | 45 | 31.6 | 4-φ14 |

| 400 | 216 | 580 | 525 | 490 | 32 | 4 | 16-φ30 | 600 | 175 | 140 | 20 | 300 | 940 | 51 | 33.15 | 4-φ18 |

| 450 | 222 | 640 | 585 | 550 | 40 | 4 | 20-φ30 | 750 | 175 | 140 | 20 | 340 | 995 | 51 | 37.95 | 4-φ18 |

| 500 | 229 | 715 | 650 | 610 | 44 | 4 | 20-φ33 | 750 | 175 | 140 | 22 | 355 | 1058 | 57 | 41.12 | 4-φ18 |

| 600 | 267 | 840 | 770 | 725 | 54 | 5 | 20-φ36 | 750 | 210 | 165 | 30 | 410 | 1163 | 70 | 50.63 | 4-φ22 |

| 700 | 292 | 910 | 840 | 795 | 40 | 5 | 24-φ36 | 750 | 300 | 254 | 30 | 478 | 1283 | 66 | 63.35 | 8-φ18 |

| 800 | 318 | 1025 | 950 | 900 | 42 | 5 | 24-φ39 | 750 | 300 | 254 | 30 | 529 | 1398 | 66 | 63.35 | 8-φ18 |

| 900 | 330 | 1125 | 1050 | 1000 | 44 | 5 | 28-φ39 | 1250 | 300 | 254 | 34 | 584 | 1498 | 118 | 75 | 8-φ18 |

| 1000 | 410 | 1255 | 1170 | 1115 | 46 | 5 | 28-φ42 | 1500 | 300 | 254 | 34 | 357 | 1608 | 142 | 85 | 8-φ18 |

| 1200 | 470 | 1485 | 1390 | 1330 | 52 | 5 | 32-φ48 | 1500 | 350 | 298 | 34 | 799 | 1876 | 150 | 105 | 8-φ22 |